cheese hazard analysis

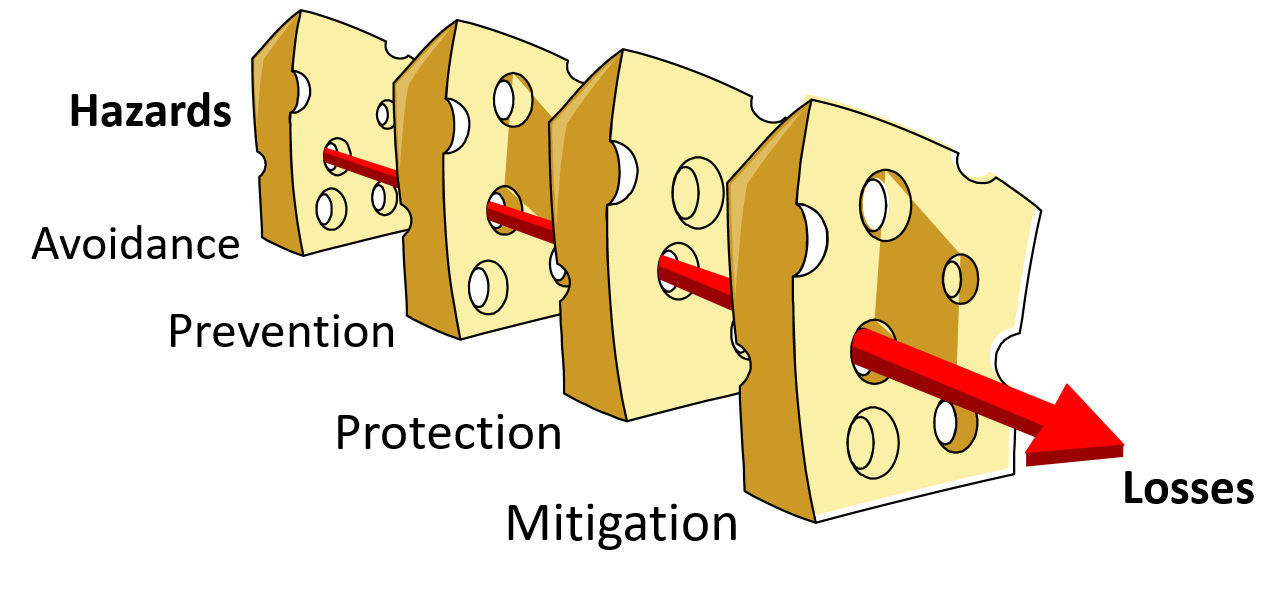

Thus the implementation of the Swiss Cheese model in patient safety is used for defences barriers and safeguarding the potential victims and resources from hazards Reason 2000. Discard soft cheese cheese that has a loose-knit curd such as some colbys and shredded or sliced cheese if it contains molds that are not a part of the manufacturing process.

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

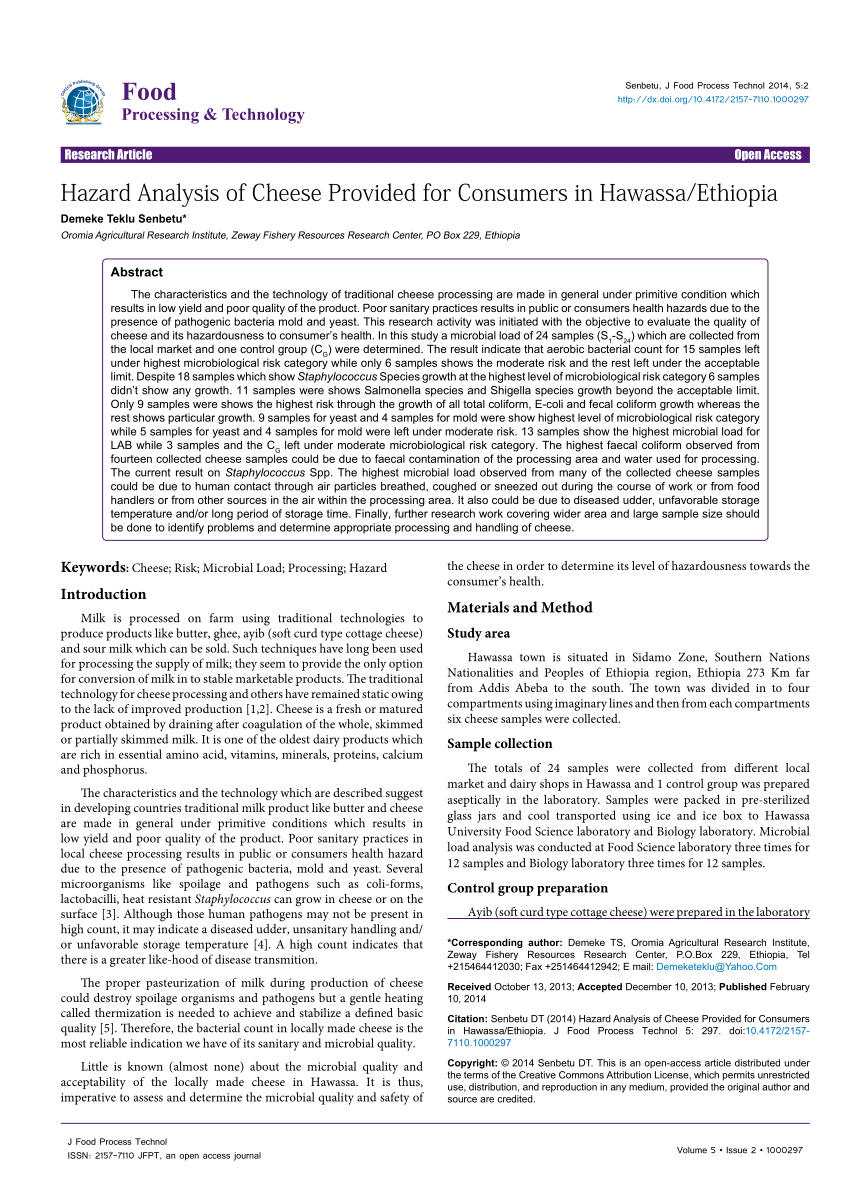

The traditional inspection and quality procedure in order to prevent the hazards in the cheese product.

. Foods with high moisture content can be contaminated below the surface. Cheese production in 2020 was 1325 billion pounds up 2 percent from 2016. Chemical Safety and Hazard Investigation.

Cheese is generally considered a safe and nutritious food but foodborne illnesses linked to cheese consumption have occurred in many countries. The Basic Idea Behind Swiss Cheese The Swiss-cheese model was initially developed by James Reason to illustrate how analysis of major accidents and catastrophes tended to reveal multiple smaller failures that allowed a hazard to manifest as a risk. It is common in the world due to distinct taste aroma and flavour.

The approach at Cargill was to break down hazards into one of four areas. Conduct a hazard analysis. Siana Abstract HACCP Hazard Analysis Critical Control Points is a system that analyzes the potential hazards related to food production identifies critical control points at which.

This is a frozen product which does not rely on intrinsic factors for stability. Wisconsin led the nation in cheese production in 2019 with 336 billion pounds. Hazards considered to be of such low risk that no control is needed.

Hazards controlled or minimised by CCPs. There are several factors that can affect the permeability of the capillaries and the ability of the salt solution to flow through them but not all such factors are affected by changes in technique. QPRAM is a virtual laboratory that will predict and characterize risks from consumption of fresh produce that result from specific behaviors and practices on farms and during the processing and.

Other top cheese-producing states include Idaho New Mexico and New York Statista. Semi-Soft Soft Cheese All Types of Crumbled Shredded Sliced Cheese. Depending on factors such as the level of contamination the likelihood of occurrence and the potential damage it can cause these food safety hazards can mildly or significantly affect public health.

Although the assessments of microbial risk in soft and low. Water activity a of cheesecake layer 090. Shredded sliced or crumbled cheese can.

Hazards controlled or minimised by GMPs. According to this metaphor in a complex system hazards are prevented from causing human losses by a series of barriers. The HACCP system for managing food safety concerns grew from two major developments.

For each hazard the section details its nature its characteristics and provides concise. Though many manufacturers obtain a HACCP certificate easily they may not apply the systematic food screening programs during all stages of the. Likewise California continued to rank second producing 25 billion pounds of cheese.

These molds can be dangerous. - Hazard analysis presented in appendix in order not to weigh on the operational part of the document. Fire at Praxait St.

Each barrier has unintended weaknesses or holes hence the similarity with Swiss cheese. A risk is a term that is commonly used to refer to a chance or likelihood of an undesirable event occurring. A food safety hazard is any biological chemical or physical property that may cause a.

Hazard analysis has been identified as one of the most demanding tasks for a HACCP team. PH of cheese layer. It is not intended to be ambient stable or to be stored refrigerated for long.

Hazard analysis and critical control points HACCP ensures product protection. Cheese curd is criss-crossed by capillaries. This applies for example to the fat content.

Several microbial risk assessments related to Listeria monocytogenes Staphylococcus aureus and Escherichia coli infections causing cheese-related foodborne illnesses have been conducted. To evaluate the current methods of analysis on hazards that appear during the processing and control procedures used in the plant. Approximately 10000 capillaries per cm 2 have been found.

This section details the main chemical physical and microbiological hazards that concern dairy products and lists the more relevant ones that are referred to in the other sections of the document. The Principles of the HACCP. A physical chemical biological or allergenic substance associated with a food commodity from harvesting to the consumers hand could contaminate food processing.

These food safety hazards constitute all of the agents that can cause foodborne illnesses or allergic reactions to consumers. Based on Fisher and Scot 2013 risk typically refers. It is a worldwide-recognized systematic and preventive approach that addresses biological chemical and physical hazards through anticipation and prevention rather than through end-product inspection and testing.

Murrays Cheese 2014 Results of Poor Sanitation It is estimated that there are 76 million cases of foodborne illnesses in the US every year causing more than 325000 hospitalizations and 5000 deaths Reduced shelf life Poor quality product Customer illnesses or. James Reason proposed the image of Swiss cheese to explain the occurrence of system failures such as medical mishaps 1-5. To set up a specific HACCP plan for this small-scale cheese plant.

As fat globules block the structure salt penetration will take longer in a. To document the HACCP plan in order to demonstrate the. Hatch D McCulloch P Travers I.

The main purpose of the Swiss Cheese model is to visualize how a hazard may be able to pass through the vulnerability of the many different measures in place. Although looking primarily at safety risks his research also indicated that human error was consistently the largest contributor to risk management failures. No chemical preservatives are used.

Dangers of Propylene Cylinders. The Swiss cheese model of accident causation is a model used in risk analysis and risk management including aviation safety engineering healthcare emergency service organizations and as the principle behind layered security as used in computer security and defense in depthIt likens human systems to multiple slices of Swiss cheese stacked side by side in which the risk of a threat. It addresses ingredient-related hazards process-related hazards and hazards that may be introduced from the food- production environment facility-related hazards.

Abstract and Figures Cheddar cheese is a hard ripened cheese with a long shelf life and without any surface Flora. Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. These weaknesses are inconstant ie the holes.

Implementation Of The Hazard Analysis Critical Control Point Haccp System To A Dairy Industry Evaluation Of Benefits And Barriers Semantic Scholar

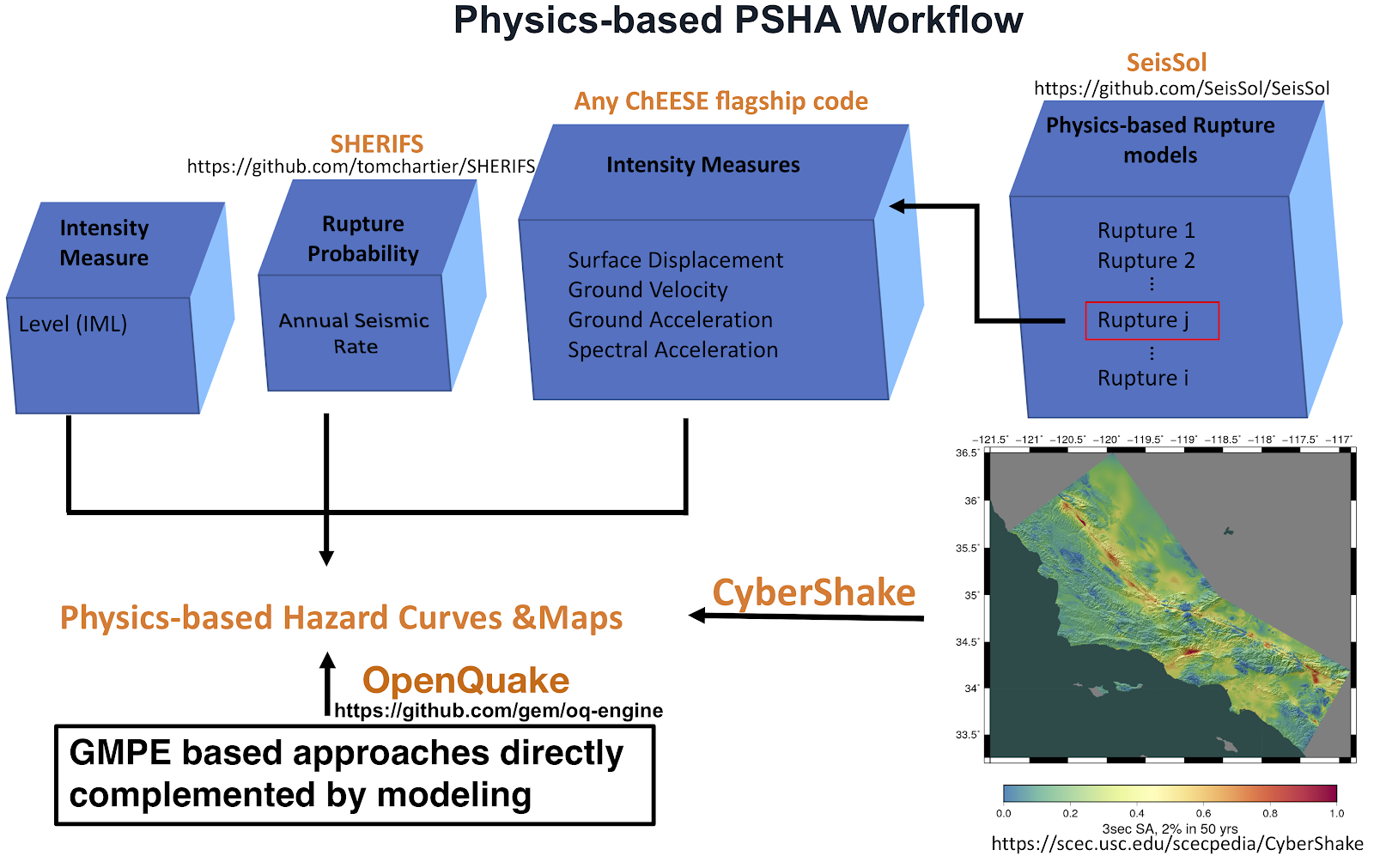

Pd5 Physics Based Probabilistic Seismic Hazard Assessment Psha Cheese Centre Of Excellence For Exascale Supercomputing In The Area Of The Solid Earth

Determinants Of Implementation Of Hazard Analysis And Critical Control Point Project In Four Selected Gouda Cheese Processing Firms In Rwanda Semantic Scholar

Hazard Analysis Of Cheese Processing Steps Download Table

Critical Control Points In Haccp System Set Up In Cream Cheese Production Download Table

Swiss Cheese And Safety Michigan Tech Research Blog

Hazard Analysis Of Cheese Processing Steps Download Table

Critical Control Points In Haccp System Set Up In Cream Cheese Production Download Table

How Swiss Cheese Can Save Our School Children By Freeman Marvin Medium

Pdf Hazard Analysis Of Cheese Provided For Consumers In Hawassa Ethiopia

Pdf Control Of Haccp System Efficiency In Cream Cheese Production Semantic Scholar

Safety In Mind Swiss Cheese And Bowties Flight Safety Australia

A Swiss Cheese Model For Reducing Biases In User Research By Biswajeet Das Ux Collective

Haccp Plan For Pasteurized Milk Download Table

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

0 Response to "cheese hazard analysis"

Post a Comment